JACKON Insulation by BEWI’s new site in Olen, Belgium (Photo: JACKON Insulation by BEWI)

RoRo StretchPack® packaging machine

for JACKON Insulation by BEWI in Belgium

At JACKON Insulation by BEWI’s newly inaugurated production facility in Olen, Belgium, a RoRo StretchPack® XL packaging machine has been installed. This advanced packaging machine plays a vital role in the new production line, ensuring that XPS construction boards are delivered to construction sites in optimal condition.

At JACKON Insulation by BEWI’s newly inaugurated production facility in Olen, Belgium, a RoRo StretchPack® XL packaging machine has been installed. This advanced packaging machine plays a vital role in the new production line, ensuring that XPS construction boards are delivered to construction sites in optimal condition.

JACKON Insulation by BEWI has already experienced the benefits of the RoRo StretchPack® technology with another machine, which consistently meet their high standards for performance and reliability. The success of this installation has led JACKON Insulation by BEWI to invest in a second RoRo StretchPack® machine for their new site in Belgium.

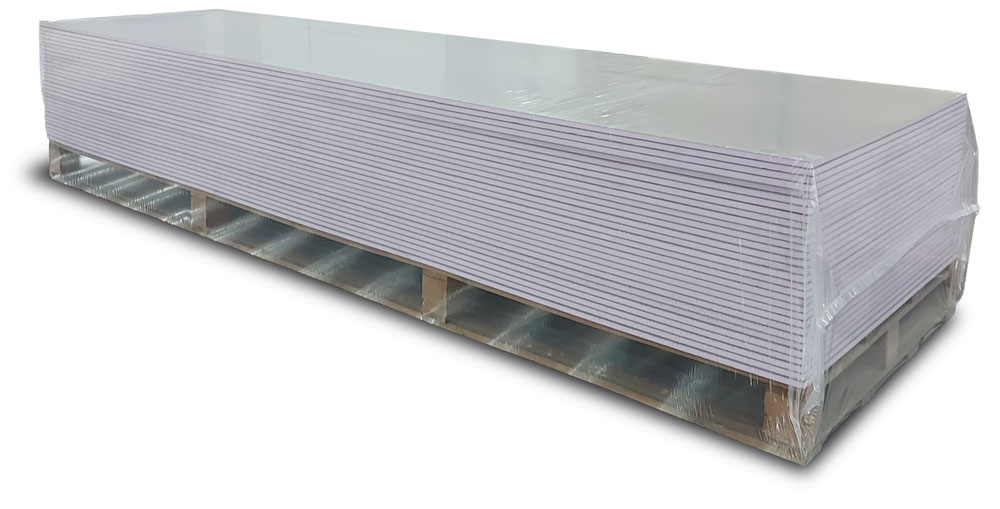

Six-sided packaging of pallets with XPS boards

The new RoRo StretchPack® XL machine is used for packaging XPS construction boards stacked on pallets. The stacked XPS boards, including the pallet, are wrapped horizontally in a stretch hood film. The stretch hood film is welded at both ends during packaging, providing six-sided, waterproof protection. This ensures the high quality and performance of the XPS boards, keeping them dry and intact during transport and storage.

The decision to invest in RoRo StretchPack® technology aligns with JACKON Insulation by BEWI’s commitment to delivering high-quality construction boards. With the RoRo StretchPack® solution, their XPS construction boards are well protected against external contamination.

“We are thrilled that JACKON Insulation by BEWI has chosen Tentoma once again for their packaging needs,” said Troels B. Mathiesen, CEO of Tentoma A/S. “Their continued trust in our RoRo StretchPack® technology underscores the reliability and efficiency of our solutions. We are proud to support JACKON Insulation by BEWI and their commitment to delivering top-quality insulation products.”