From production site to end-user, building materials are exposed to dirt and moisture during handling, transport, and storage. In the worst-case, this could degrade the product quality so it does not meet your customers’ requirements.

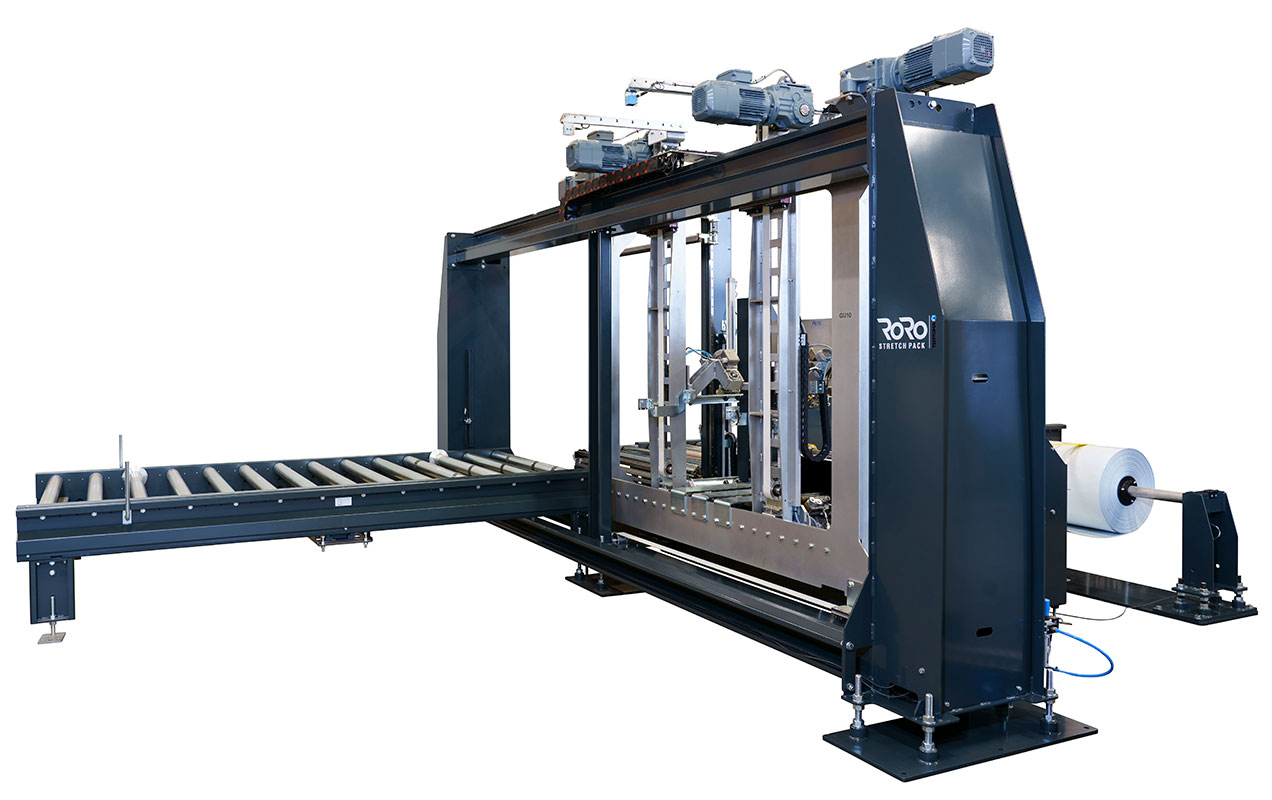

An effective way to eliminate this risk is to seal your products, so the packaging will be 100% dust and waterproof. This can be done with RoRo StretchPack® machinery using horizontal stretch hood packaging.

Six-sided sealed packaging

RoRo StretchPack® ensures a complete six-sided packaging for full waterproof sealing of different kinds of building products. If required your products could also be packed five-sided or four-sided. The packaging quality provides:

- Six-sided sealed packaging

(or four- and five-sided) - 100% dust and waterproof

- Optimal for print and branding

- Improved load stability

Automate packaging and free up labour

By utilizing a RoRo StretchPack® machine you can fully automate your packaging of building products with lengths on up to 8 m. The packaging is done in one automated operation and doesn’t require e.g. a heat shrink system. This frees up space on the production line. The machinery is developed to give you a high packaging speed, with a high up-time:

- Large film capacity reduces film roll changes

- Fast change of film roll (max. 5 minutes)

- Automatic shift between different film and roll sizes

- Minimal cleaning and maintenance

- Packaging of both batch and random order possible

- No heat shrink required

Utilize film for branding

In addition to the protection of the products, the film can improve the load stability depending on the product types.

The film is also suitable for print with very few limitations. This can be utilized for branding your logo or other types of graphic. Your products will then appear nice and clear when they reach end-users.

The XL RoRo Stretch Pack® machine is developed with support from Markedsmodningsfonden.

Reduce your film consumption by up to 60%

Horizontal stretch hood packaging is a film saving solution compared to other packaging solution such as both wrapping and heat shrink packaging. We have seen reductions in film consumption between 25-60%, which also leads to a significant reduction of the film cost.