Ensuring dry insulation materials arrive on the construction site is vital for successful building projects. Moisture in the mineral wool can compromise the insulating properties and may lead to other problems down the line. Therefore, waterproof sealing packaging of mineral wool insulation is crucial.

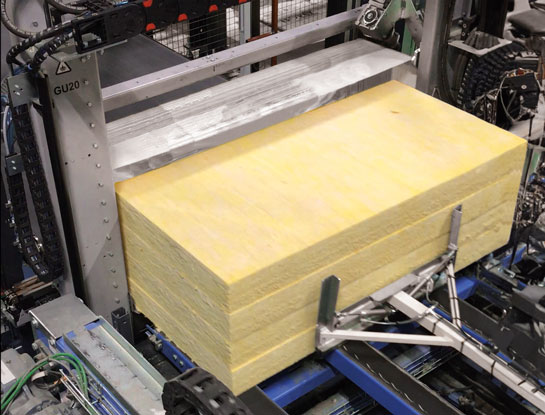

With a RoRo StretchPack® packaging machine, you can fully encapsulate mineral wool insulation using six-sided packaging. Additionally, you will reduce your operating costs.

Six-sided sealed packaging

RoRo StretchPack® offers a 100% waterproof packaging solution for insulation materials. Your products are packed into a tubular stretch hood film, which is welded at the ends to ensure 100% waterproofness. This provides the following benefits:

- Six-sided sealed (or four/five-sided)

- Dust and waterproof

- Smooth and uniform

- Optimal for print and branding

- Improved load stability

RoRo StretchPack® can also do four- and five-sided packaging, e.g. if you prefer to have your product in both primary and secondary packaging.

Significant savings on film and energy consumption

Thanks to the unique characteristics of the tubular stretch film, RoRo StretchPack® achieves a secure, single-layer packaging solution. Based on our customer experiences, transitioning to RoRo StretchPack® typically results in film savings ranging from 25% to 60% compared to traditional packaging methods.

RoRo StretchPack® streamlines the packaging process for mineral wool by combining packing and protection into a single operation. With this innovative solution, there’s no longer a requirement for a separate heat shrink process. Not only does this eliminate potential challenges associated with heat shrink (such as packaging quality, fire risk, and cleaning), but it also leads to energy cost savings. When a RoRo StretchPack® machine replaces a heat shrink packaging line we typically see the following savings:

- Film consumption reduced by up to 60%

- Energy reduced by up to 90% - cold packaging technology

- The length of the packaging line is reduced - only one operation

- Maintenance costs are reduced

Designed to increase speed and capacity

The RoRo StretchPack® packaging machines utilize our extensive expertise gained from collaborating with top insulation industry manufacturers. We’ve created a variety of features and customizable options to tailor the machine to your specific packaging requirements, ensuring smooth integration into your production line.

Ensuring compliance with the demanding needs of industrial production, which may run continuously, requires essential features like high capacity and uptime. The RoRo StretchPack® packaging solution is characterized by:

- Large film capacity on a film roll - up to 6 km depending on thickness

- Fast change of film roll - 2-4 minutes

- Automatic shift between different film sizes

- Minimal cleaning and maintenance

- Packaging of both batch and in random order

Utilize the packaging film for branding

In addition to protecting the mineral wool, RoRo StretchPack® provides sleek and consistent packaging that showcases your products nicely to customers. You can have your logo or a product design printed on the packaging film, setting your products apart from competitors and strengthening your brand identity.

The single-layer packaging guarantees that printed graphics appear clear and undistorted. Unlike traditional heat shrink processes, the cold packaging method ensures the film remains flat and intact, avoiding any curling or crumbling caused by heat exposure from a shrink oven.

Remove the strapping process

Using RoRo StretchPack, you can remove the strapping process from your packaging line. Bearers and spacers can be included inside the packaging film. The stretch hood film will then hold them against the bottom of your products. By removing the strapping process, you can reduce the number of operations on your packaging line.